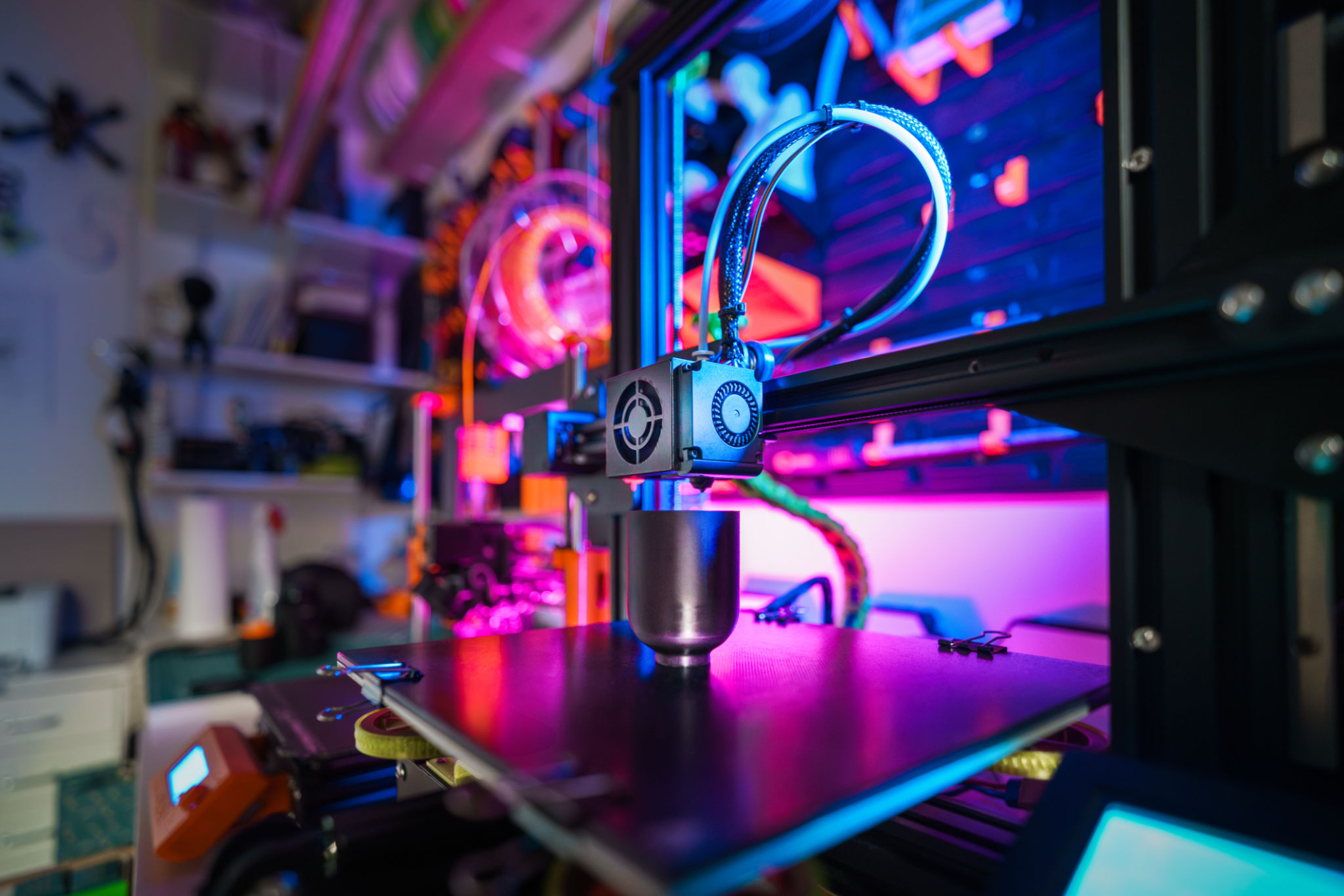

Common Misconceptions About 3D Printing: Debunked!

AG

3D Printing Is Only for Prototyping

One of the most common misconceptions about 3D printing is that it is solely used for prototyping. While it's true that 3D printing excels in rapid prototyping, its applications extend far beyond this. Industries such as healthcare, aerospace, and even fashion are leveraging 3D printing for final product manufacturing. This technology allows for the creation of complex geometries and customized products that would be difficult or impossible to achieve with traditional manufacturing methods.

3D Printing Is Too Expensive

Another prevalent myth is that 3D printing is prohibitively expensive. While the initial cost of a high-end 3D printer can be significant, the overall cost-effectiveness of 3D printing can actually be quite favorable. For instance, it reduces waste by using only the material necessary for the object being printed. Additionally, the ability to produce parts on-demand can save on storage and inventory costs. There are also more affordable desktop 3D printers available that make the technology accessible to small businesses and hobbyists.

Material Costs

It's also worth noting that the cost of materials for 3D printing has decreased over the years. From plastics to metals, a variety of materials are now available at competitive prices. This makes 3D printing a viable option for both large-scale production and small-scale projects.

3D Printing Is Too Slow

Many people believe that 3D printing is too slow to be practical for large-scale manufacturing. While it is true that 3D printing can take longer than traditional methods for certain applications, advancements in technology have significantly reduced print times. Newer printers and techniques, such as continuous liquid interface production (CLIP) and multi-jet fusion, are capable of producing parts much faster than older methods.

Batch Production

Moreover, 3D printing allows for the simultaneous production of multiple parts in a single print job. This batch production capability can significantly speed up the manufacturing process, making it more efficient for producing multiple units.

3D Printing Is Limited to Plastics

Another misconception is that 3D printing can only use plastic materials. In reality, 3D printing has evolved to include a wide range of materials. From metals like titanium and aluminum to ceramics and even bio-materials, the versatility of 3D printing materials is continually expanding. This makes it possible to create everything from durable mechanical parts to intricate jewelry and medical implants.

Composite Materials

Additionally, composite materials that combine different substances to enhance properties such as strength, flexibility, and heat resistance are also available. This further broadens the scope of what can be achieved through 3D printing.

3D Printing Is Not Environmentally Friendly

Some people argue that 3D printing is not an eco-friendly option due to the energy consumption and material waste. However, 3D printing can actually be more sustainable than traditional manufacturing methods. It typically uses less material, as it builds objects layer by layer, minimizing waste. Furthermore, advancements in recycling technologies allow for the reuse of 3D printing materials.

Energy Efficiency

Modern 3D printers are also becoming more energy-efficient. Innovations like low-temperature printing and the use of renewable energy sources are helping to reduce the environmental impact of 3D printing.

In conclusion, 3D printing is a versatile, cost-effective, and increasingly sustainable technology that is breaking free from the misconceptions that have long surrounded it. As advancements continue, its applications will only grow, making it an invaluable tool across various industries.